Construction Management System With Bim (CTMS-B)

Project Background

The consortium from Magicsoft Asia Systems Pte Ltd(Magicsoft) have been working on one stop solution to provide construction companies with a productive and efficient way to manage and monitor the construction processes. The consortium is now keen to use the experiences gained to further enhance the solution by incorporating BIM data into the CTMS software to stream line and monitor the process of building processes to minimize the human error, minimize the wastage, increase productivity, and at the same time providing traceability of the building materials.

Problems to Address

- 。Under utilization of BIM information during construction processes.

- 。No real time update of construction progress to the BIM model. Different stake holders of the project do not have real time access to the project progress.

- 。No automation of ordering construction materials based on materials usage and prediction. Delays caused by shortage of materials turned into lower productivity and cost.

- 。No real time traceability of the construction materials – not knowing the exact stock levels and location of the materials.

- 。No specification and standard installation processes with refer to BIM elements. All information are on paper and based on experience and practice of different contractors.

- 。No data analysis to automate the risk assessment and prediction of result based on different processes.

- 。No detail streaming and recording of CCTV video during important installation for future reference or analysis.

Solution Design

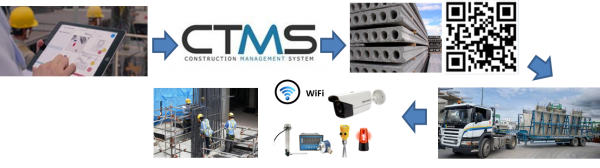

Solution Processes

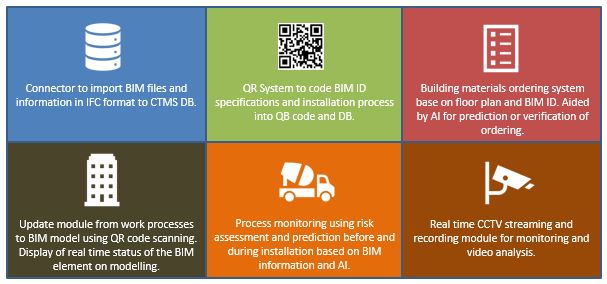

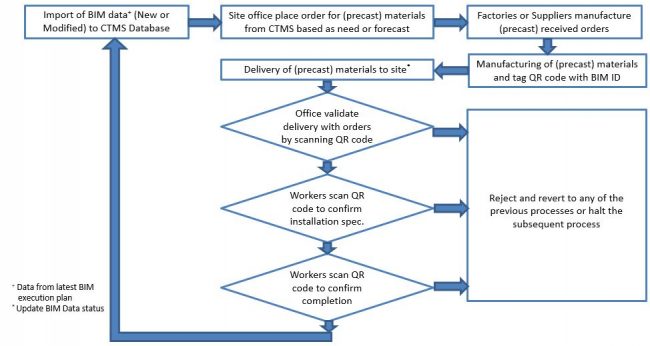

Construction companies will lace order of the (precast) materials from the site using the floor plan or BIM information, where factories or suppliers can receive the order real time, manufacture them and schedule the delivery to site base on the order. Once (precast) materials reached the site, site workers will install the (precast) materials according to BIM data from the software to minimum the human error and the processes will be subjected to AI modelling for risk assessment and prediction. And along the whole process chain, the materials will be traced using QR code and CCTV, status will be updated base on different stage of the construction processes.

Solution Components

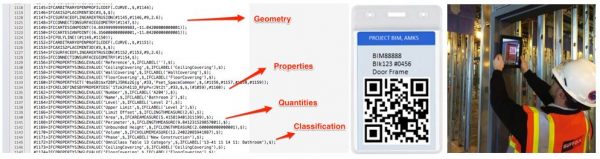

BIM Data and QR Code

New or modified BIM Data preferably in OpenBIM format or any prevailing open standard such as IFC standard will be imported and stored in the database base on each construction company and project. The BIM Elements ID of individual (precast) materials will be QR coded during manufacturing and printed QR tag with water proof closure can be embed to the (precast) materials such as the following.

Cobie Spreadsheet

Construction Operations Building Information Exchange (COBie) is a non-proprietary data format for the publication of a subset of building information models (BIM) focused on delivering asset data as distinct from geometric information. In the Cobie there are 20 sheets, they are: Instructio, Contact, Facility, Floor, Space, Zone, Type, Component, Systems, Assembly, Connection, Spare, Resource, Job, Impact, Document, Attribute, Coordinate, Issue, Picklists. CTMS using COBIe as source of truth data, mean that data on the Cobie spreadsheet will be imported to CTMS database and used to be a summary of drawing file (exclude geometry).

Construction Management System (CTMS, edata.sg)

CTMS is a construction management software that has been serving construction companies for managing the assets, permit to work, attendance among other construction processes. It will be modified to add in features where users will be able to scan QR code to see the order details of BIM element, presentation of it on the site map, the specifications and installation processes of it and mark the starting/completion of the installation. Users or the CTMS can and will revoke processes that did not meet the requirements.

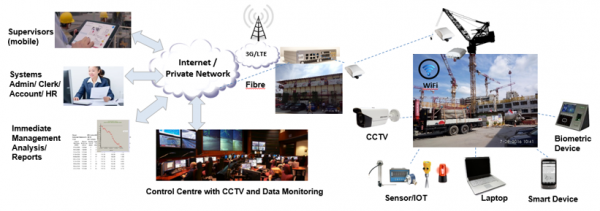

IP Infrastructure and CCTV

The whole construction site would be WiFi enabled using the IOT gateway LILEE SYSTEMS connected to LTE or fibre internet and Ruckus wireless bridge and WiFi access point to facilitate the using of CTMS software. Smart devices with camera or wearable camera will be incorporated in to provide close range recording of video or photos of the processes for monitoring and training purposes. Video from Drone will be providing the construction update of the site and CCTV placed at strategic locations including the crane will be able to track the movement of truck with building materials, storage of them, and real time feed of video to site supervisors and crane operators.

Deliverables of the Solution

Stage 1 POC

-The successful import of BIM data in IFC format to CTMS Database

-Generation of QR code base on BIM ID and element details

-Update of status on BIM elements to CTMS Database using QR code

-Showing alert generated by AI due to conflict of processes

-Real time streaming and recording of CCTV

Stage 2 Implementation

-Prediction of building materials for ordering

-Ordering of building materials based on Floor Plan or BIM ID

-QR code provides BIM element specifications and installation processes

-Real time tracking and update of BIM element status to 3D model in CTMS

-Real time streaming and tagging of CCTV records from CTMS based on different processes

-Providing access to different stake holders of the project to view the 3D model

English

English  China

China  Japan

Japan  Indonesia

Indonesia